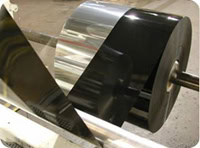

Side-By-Side PET Plastic Extrusion

Our customer SXS PET extruded sheet can be cut and formed into a range of packaging products, including thermoform blisters, clamshells, trays, and a variety of packaging solutions. The exceptional clarity, impact performance and formability of our SXS PET extrusion make it best suited for packaging, thermoforming, as well as laminating applications. Available in AB and BAB extrusion process. Our dedicated engineering and design team can assist with your custom project needs. See link below for profile width and dimensions.

Specifications:

- General Capabilities

J.I.T.

Contract

O.E.M.

- Industry Focus

Aerospace

Automotive

Consumer Packaging

Industrial Packaging

Food Packaging

Construction

Electrical

Medical

Transportation

- Resistance Characteristics

Acid

Strong Oxidizer

Alkalis

Hydrocarbon Solvent

Alcohol

Fat

Grease

Oil

- Colors/Styles

Clear

Custom Colors

- Coating

Anti-Static

Anti-Fog

- Industry Standards

AIB

ANSI

ASME

ASTM

FDA Certified

GMP

ISO

Kosher Certified

Mil-Spec

- Applications

Thermoforming

Braze Fabrication

- Extrusion Product

Roll Stock

- Extrusion Product Form

Profiles

Rods

Shapes

Sheet

- Extrusion Features

Flexible

Food Grade

High Temperature

Thin Gage

High Impact

Multi Color

- Additional Services Provided

Matte Finish

Online Gaging

Topical Coating

Sheet Finish- Translucent

- Opaque

Transparent

- Gauge

Min: 0.015 in (0.381 mm)

Max: 0.040 in (1.016 mm)

- Width

Min: 15 in (381 mm)

Max: 54 in (1371 mm)

- Core Size

3 in

6 in

- Roll O.D.

Min: 29 in (736.6 mm)

Max: 40 in (1016 mm)

- Specific Gravity

1.335

- Shrinkage

2.0% to 5.0%

- Yield

20,810 in2/lb/Mil of thickness

- Tensile Strength at Yield

Min: 8,000 PSI

Max: 9,000 PSI

- Flexural Modulus

Min: 325,000 PSI

Max: 370,000 PSI

- Intrinsic Viscosity

>=0.74

- Light Transmission

>=90%

- Haze

>=2%

- Clarity

>=99%

- Temperature Range

Min: 0° F (-18° C)

Max: 150° F (66° C)

- Gauge Tolerance (+/-)

5%