MATERIALS

The wide range of gauge and width capabilities offered in APET, RPET, CPET and Side-by-Side by Advanced Extrusion is augmented by our team's strong knowledge of the thermoforming process and has the ability to offer on-site technical assistance if it is desired.

CAPABILITIES

Side-By-Side PET Plastic Extrusion

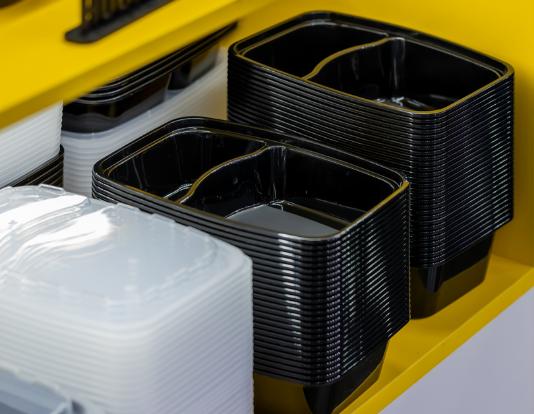

Our customer SXS PET extruded sheet can be cut and formed into a range of packaging products, including thermoform blisters, clamshells, trays, and a variety of packaging solutions. The exceptional clarity, impact performance and formability of our SXS PET extrusion make it best suited for packaging, thermoforming, as well as laminating applications. Available in AB and BAB extrusion process. Our dedicated engineering and design team can assist with your custom project needs. See link below for profile width and dimensions.

CoExtrusion – The process to convert two or more materials into a single piece

For your unique and custom projects, we at Advanced Extrusion, Inc. are capable of producing up to 7 layer structures in the creation of your material. Tailored to meet your Oxygen Transfer Rates (OTR), and Moisture Transfer Rates (MTR). ShurSeal™ available to assist in your sealing property requirements.

ABOUT US

Advanced Extrusion, Inc. is a close tolerance extrusion house utilizing state-of-the-art equipment to produce polyester roll stock for the thermoforming and laminating industries. This equipment, combined with a team that has more than 35 years of experience in the extrusion industry, results in a product that meets all our customers critical requirements.

Learn More

Quality Statement

Sustainability

CERTIFICATIONS